Prodotti

Vireg tondi illustrati tat-Tungsten Carbide ta' preċiżjoni għolja

Introduzzjoni tal-Prodott

Vireg tal-karbur jintużaw prinċipalment għal bits tat-tħaffir, cutters tat-tħaffir tat-tarf u winċijiet. Jistgħu jintużaw ukoll għat-tqattigħ, l-ittimbrar u l-għodod tal-kejl. Jintużaw fl-industrija tal-karta, l-ippakkjar, l-istampar, l-ipproċessar tal-metalli mhux ferrużi. Barra minn hekk, jintużaw ħafna fil-magni tal-cutters tal-azzar b'veloċità għolja, cutters tat-tħaffir tal-karbur, cutters tal-karbur simentat, għodod tat-tqattigħ NAS, cutters tal-avjazzjoni, bits tal-karbur simentat, bits tal-qalba tal-cutter tat-tħaffir, azzar b'veloċità għolja, cutters tat-tħaffir konikali, cutters tat-tħaffir metriċi, cutters tat-tħaffir tat-tarf mikro, pilota taċ-ċappetti, għodda elettronika,fajl li jdur tal-karbur, għodda tal-karbur simentat, eċċ.

Dettalji tal-Prodott

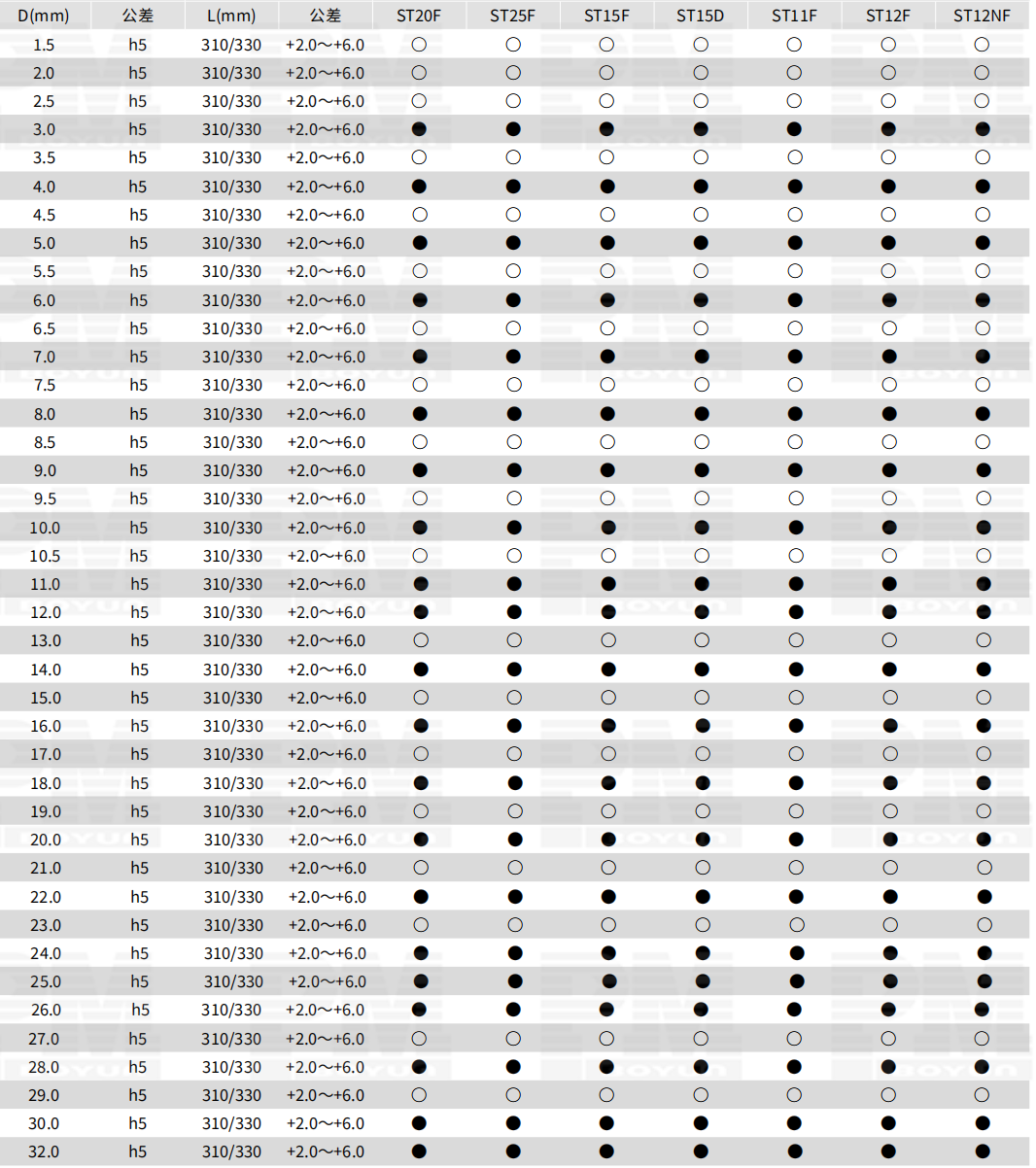

Daqsijiet Referenzjati

Tabella tal-Grad tal-Materjal

| Introduzzjoni għall-Grad tal-Vireg tal-Karbur | |||||||

| Grad | Ko % | Daqs tal-qamħa tad-WC | HRA | HV | Densità (g/cm³) | Saħħa tal-liwi (MPa) | Ebusija tal-frattura (MNm-3/2) |

| KT10F | 6 | Submikron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfin | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometru | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Multa | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submikron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfin | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfin | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometru | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submikron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submikron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submikron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submikron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfin | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfin | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfin | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometru | 92.0 | 1670 | 13.8 | 4800 | 10 |